Test of HILTI anchors pulling-out of UDK aerated concrete

- Details

- Published: Friday, 17 October 2014 10:07

- Written by UDK Gazbeton

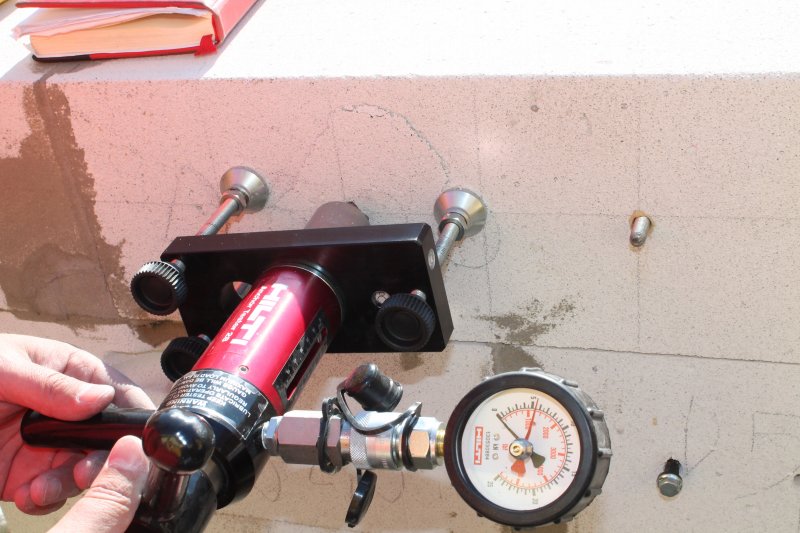

There have been conducted tests of4 types HILTI anchor fittings of UDK aerated concrete of different density class produced by UDK LLC.

On the UDK company premises in cooperation with Yevgeniy Balyhin, Head of technical support group of HILTI company, there have been tested 4 types anchor fittings of pulling out of different density class aerated concrete produced by UDK company.

For tests we selected particular blocks and prepared some segment wall settings from UDK blocks of D350, D400 and D500 density class with В2,0 andВ 2,5 (С2,0 and С2,5) concrete compression class. There were used 2 types of mechanical anchors - HRD 10x100 and HRD-U 10/30 and 2 types of chemical anchors - HIT-MM и HIT-HY70. To set the anchors you should drill a hole of the same diameter that the anchor has. Shock-free drilling. In this case we drilled the holes of 10 mm diameter, 100 mm depth for mechanic anchors and of 12 mm diameter, 100 mm depth for chemical ones (with 12 mm sprig).

After the drilling remove the dust from the hole.

After the drilling remove the dust from the hole.

Chemical anchors are two-component. To fill in the hole with mix it is used a special gun with mixing head. It is set fitting element into the hole and hardening time (depending on the air and base temperature) is 45 min in this case.

Chemical anchors are two-component. To fill in the hole with mix it is used a special gun with mixing head. It is set fitting element into the hole and hardening time (depending on the air and base temperature) is 45 min in this case.

According to the results of further anchor testing of pulling-out of UDK aerated concrete of different consistency class we put down following data:

According to the results of further anchor testing of pulling-out of UDK aerated concrete of different consistency class we put down following data:

1. For HRD-U 10/30 - from 0,8to 1,8 кН (≈80-180 kgf);

2. For HRD 10x100 - from 1 to 2,2кН (≈100-220 kgf);

3. For HIT MM - from 4,5to 6 кН (≈450-600 kgf);

4. For HIT-HY70 - from 5 to 6,5кН (≈500-650 kgf)

Pull-out test protocol of HILTI anchors from aerated concrete.

Pull-out test protocol of HILTI anchors from aerated concrete.