Autoclaved aerated concrete (AAC) – the story of a low-weight material

- Details

- Published: Thursday, 13 February 2014 10:44

- Written by UDK Gazbeton

THE PRESENT SITUATION

AAC is attractive on the world market. The production is growing by some 5 Mm3 per year, while the total demand will reach 100 Mm3 in the year 2010, according to H. Bagheri (2006). It is a high-class building material made of simple or even waste ingredients (sand and/or fly ash), with a limited amount of mineral binders (lime, cement). Foaming is generally activated by aluminium powder. The elevation to a higher level is an example of the current trend towards material economy, activated through a well-adapted, low-temperature manufacturing process. The pressurized autoclaving (180-200°C, at about 1 MPa for around 10 h) converts the minerals chemically into a strong crystal structure of torbermorite. And the level of embodied energy is relatively low. Cutting with wires is very accurate, which allows for precise block geometry and masonry with thin bed (1-3 mm) mortar.

In practice AAC now appears in dry densities from 275-400 kg/m3 (insulating densities) to 450-750 kg/m3 (structural qualities). It is used for plain masonry or insulating purposes and for reinforced components such as lintels, roof/floor and wall panels. The creep factor increases with lowering the material density. This may have an important influence on load-bearing walls with a low content of reinforcement. In practice, the density 500 kg/m3 is a good compromise in such cases. Horizontal members have reinforcement also on the compressed side, which make them less sensitive to long-term effects. Investigations of up to 70 year-old horizontal elements confirm to this fact. A lower density is compensated by more steel, which has a fourfold purpose, to resist tension, compression, shear and supply anchorage.

The span limit of a horizontal member was traditionally 6 m. The amount of steel was then still moderate. Increasing the span led to a rapid increase of steel. Siporex, a Swedish producer, expanded the mould to 8.0 m, but in practice the limit was held at 7.2 m with densities 500 or 600 kg/m3, (Lättbetonghandboken, 1993). One factor of critical importance was the deflection under dead weight – a test member of 8 m span had a substantial hang.

BCE

A completely different solution to the span problem is given by the BCE technology, originally suggested by one of the authors in the early 1990s, (Hellers B.G. & Lundvall O., 1992). It is a hybrid combination of AAC (PFA or sand), and HPC (High Performing Concrete) and has a special attraction to a block producer, who wants to expand his production to a complete building system. The basic idea behind BCE was to expand the capacity of AAC into 9 m for floor panels and 12 m for roof panels. The units are composed of blocks, stacked in vertical or horizontal directions in a second production stage. The compatibility is secured by pre-stressing, which is carried by the HPC-component, while AAC is an "in-fill" component, building up the body of the structure. The pre-stressing is designed to eliminate the dead weight deflection. This production is well adapted to CAD/CAM conditions, applied to a specific project. The combination is material saving in that concrete is used for compression but also for shear and anchorage of the reinforcement. Three out of four requirements on steel in a genuine AAC-panel are eliminated. Typically, coming from the AAC-side, 75% of the steel is saved, while 75% of the concrete and half the embodied energy is saved (Aroni, 1993), if you come from the pure concrete side (HDelements, hollow core decks). It indicates that going from concrete to BCE, half the emission of carbon dioxide is saved. A complication comes from handling two different concretes. The BCE project is still being developed.

PROPERTIES IN SHORT

– The embodied energy of AAC is comparatively low, 1.0 GJ/m3 (one third of concrete).

– The density of AAC varies between 275 (insulating quality) and 750 kg/m3 (structural quality).

– The conductivity (W/mK) of insulating materials is in practice 0.08 (275), 0.09 (350), 0.10 (400).

– The characteristic compressive strength (N/mm2) of AAC is 2.3 (450), 3.0 (500), 5.0 (600), 10.0 (750) (sand recipe).

– The characteristic compressive strength (N/mm2) of AAC is 2.9 (460), 3.6 (600), 7.3/8.7 (750) (PFA recipe).

– The creep factor is 0.5 (750), 0.7 (600), 1.0 (500), 1.5 (450) (sand recipe).

– Reinforced panels in practice are made of genuine AAC up to 6.0/7.2 m span (sand recipe). Reinforced members cannot be made with a genuine PFA-recipe.

– Reinforced panels are made in hybrid technology (HPConcrete/AAC:PFA recipe or sand recipe) up to 9.0 m span (roof panels up to 12.0 m).

– The modulus of elasticity (N/mm2) is 1 200 (450), 1 700 (500), 2 500 (600), 4 000 (750).

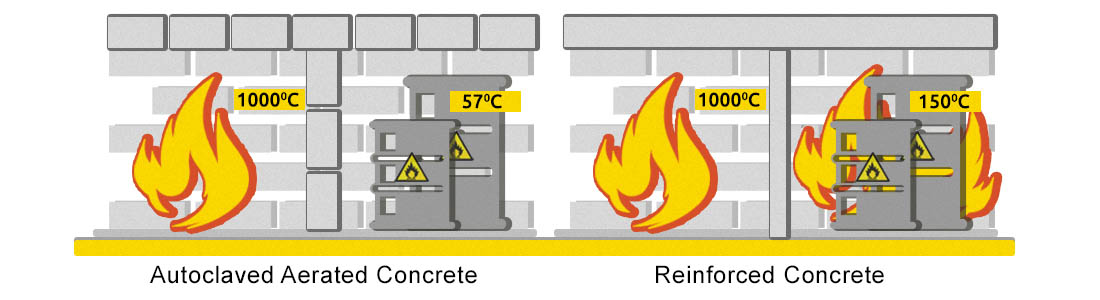

THE BEGINNING OF AAC

It all began in 1923, when a Swedish architect, J Axel Eriksson, almost by chance, discovered the possibility to use an autoclaving process to stabilize a mix of slate and burnt lime, foamed by aluminium powder. It had very limited moisture-depending shrinkage (in older literature (Ytong, 1942), it is claimed that its shrinkage is nil!). A patent was granted in 1924, but it took a full five years, until 1929, before the invention was commercially exploited, by Yxhults stenhuggeri AB, a natural stonemasonry, converting to a producer of artificial stone blocks. It was a daring step by the industrialist, Carl August Carlén, soon paying off, since the market was anxiously looking for an insulating masonry material. Sweden had experienced a serious energy shortage after WW1. Ytong, as the material was named after 1940, was widely accepted for its combination of desirable properties, load bearing, heat and sound insulating, fire proof and durable, resisting moisture rot and insects. Reinforced components wereproduced after 1933/34 (Ytong, 1954). The reinforcement in lintels was embedded in ordinary concrete, which was covered on both sides by AAC (Ytong, 1942). To our knowledge, this is the first case of hybrid combination of two concretes, an idea now recurring in the BCE-system, previously introduced. Still, Ytong has remained, first of all, a block producer.

The immediate success of Eriksson´s product soon attracted domestic competition. In the case of Carlsro kalkbruk at Skövde, the competition was of a friendly kind, built on exchange of experience. The competitor had a reputation for producing plain foamed concrete blocks since 1924 (Rönnow, 1948) and it later invested in autoclaves, following the example from Yxhult, in order to stabilize the product. The modernized production of AAC started in 1932. The company name was changed to Skövde Gasbetong AB in 1943 and again to AB Durox in 1964/65, taking the company name from its AAC product. The Durox name is now related to a Dutch group, still producing AAC in more than ten plants around the world, of which nine are in Europe.

A much more severe situation arose, when Siporit (from 1937 Siporex) was launched on the Swedish market in 1934, (Rosenborg, 1998). This material was made of a full cement-based recipe, developed as an alternative to the older slate/lime composition, used by Eriksson and others. The original purpose of Siporex was to form a complete building system, including plain blocks and reinforced products. Lintels were available from the start and roof elements the year after (1935). Typically, the proportion of reinforced products from Siporex exceeded 60% (1964), whereas Ytong´s proportion was always far less. On a European scale, the relation has remained low, 16 % in 1991 (Dubral, 1992), which indicates that AAC as a material was generally approached on a rather low level. It is believed that the current tendency is much in favour of reinforced material, forming components of complete building systems, a higher level of approach. Also, present architecture favours a free hand in choosing components, which are designed to project, beside any standard of sizes.

A Danish group, H+H A/S (Henriksen og Henriksen Aktieselskab) was formed in 1937. Later, it has merged with the British company Celcon Ltd. and it is currently expanding into Eastern Europe, through buy-out of production facilities, where PFArecipes were established after WW2. Celcon had initiated the use of PFA, replacing siliceous sand, in their products, already after 1955.

The spread of AAC technology around the world indicates that the market has been ripe for this kind of product and that maintaining patent rights has been difficult, indeed. It was long tried by Ytong AB, opposing Siporex AB, which ended in an agreement, based on a modus vivendi. Meanwhile, other producers, such as H+H A/S, tried their luck on the market with a long-term success.

THE INITIATIVE OF HEBEL

Another recipe for making AAC, the third to appear and probably inspired, like Siporex (Rosenborg, 1998), by the German material Mikroporit, was developed at the technical universities in Aachen and Stuttgart after 1942 (Schramm, 2005). It is more than likely that an inspiration came from the Siporex patent of 1937. Whether the rights were in fact violated under the war conditions is still an open question. But the researchers were certainly aware of the sensitivity of traditional wooden floorings by war actions – in 1942 the bombing of German cities started causing devastating firestorms, fed by an extensive use of wood material in buildings, especially in floorstructures, all the way from medieval times up until 1935 (Berg, 2006). (Some roof structures are still made of wood, e.g. in Scandinavia.) The walls and chimneys were normally brick structures, which remained standing after all that could burn had disappeared (Friedrich, 2002). Under war conditions, it was concluded that a new building material must be fireproof and be made of simple materials in a process of low stress on resources. This is a fully modern aspect, important in our times, when we must, for climate reasons, favour efficient solutions to building material supply, measured by some sharp resource or energy index. AAC has a low embodied energy compared to most other products.

Josef Hebel, a Bavarian contractor of high reputation since 1926, was informed about the new material, AAC, through the Generalbaurat of Munich, Hermann Giesler, who organized a meeting with important contractors of Southern Germany, on request from the Reichsregierung (L Hebel, 2008)! J Hebel was commissioned some time in 1941-42 to visit the new AAC-factories (Siporex) in the Baltics (Tallinn and Riga) to learn about reinforced panel production (Rosenborg, 1998). This is a surprising piece of information, not that a capable engineer was assigned to industrial espionage, although with Swedish consent (Jönsson, 2009), but that this happened in war-time, when the German industry, by Führerbefehl, was fully geared to belligerent production. In fact, it was a downright crime to engage in anything beside the purpose of warfare itself. Obviously, the in-house and the public policies did not match! Some kind of accepted disobedience must have characterized the Wirtschaftsministerium, where a man like Otto Ohlendorf was open to long term planning for Germany, despite the prohibition (Herbst, 1982). It is not known whether there was in fact a connection between Ohlendorf and Giesler, but it is a sign of common sense that there were good people in the time of the Third Reich, who were preparing for other conditions than the current. Or were they so convinced that the war would be won, one-way or the other? Not until the 9th of Sept 1943, was the dangerous situation altered by the Führererlass allowing the production of emergency housing for the many unfortunate people, victimized by the bombing. It is highly probable that the Hebel production of AAC at Memmingen, starting in March 1943, was part of the programme. Josef Hebel expanded his business by acquiring an abandoned silicate brick factory at Emmering later that year, which had operative autoclaves, ready for use. His office in Memmingen (since 1921) was bombed to pieces in 1945, just before the end of the war. He had then developed his production into reinforced panels, cut in shape from soft material by thin wire. Wire cutting was an old technology, used e.g. on cheese, but now subject to patent application by Ytong (1942), (Byttner, 1968). It is very likely that Hebel knew about this application.

Josef Hebel was a capable engineer but not a true inventor himself. The technology that he applied in the production, starting again in 1948 at Emmering, was a wise selection of available procedures. The AAC recipe was German, but the reinforcement and the cutting technologies came from Sweden. The initial money came from the Marshall aid to Germany. Hebel specialized in reinforced panels and elements, a profile close to that of Siporex. In 1961 the first home was built by Hebel and the next year another division, Hebel House, was formed to concentrate on residential projects throughout Germany. Hebel has since then swallowed the Siporex plants on several markets. As late as in the 1980s, (Wittmann, 1992/Pytlik & Saxena) the number of production sites was about equal, or 35, between the two companies. In 1994, there were 45 plants named Hebel. In 2002 (Charleston RBJ, 2002) the number of Hebel plants was 115, growing by on average with 4 new plants per year. The identity ofSiporex has eventually been lost to Hebel. The success of Hebel´s brand of AAC, throughout the world, is a proof of his high engineering status, combined with superior management. The total number of plants in the world was exceeding 300 in 2004 (Budwell, 2004), of which Hebel had a 40% share. His name has become a brand in itself.

FURTHER STEPS OF DEVELOPMENT

The AAC material, combined with reinforcing steel, forms a building system, to be used exclusively or in combination with steel, concrete and sometimes wood. The composition of AAC has been refined to include waste materials (already in the 1950s, based on patents from the 1930s !), such as PFA (Pulverized Fuel Ash), class F, replacing part of the sand commercially, or being the only source of siliceous matter, eliminating the grinding process. This is an environmental friendly step, working well with lower densities. At present, it is being tried to use such compositions with reinforced products. According to available experience (Siporex), it was not possible to replace more than 70% of the sand in order to avoid longitudinal cracking, but this conclusion is being questioned by other producers, such as H+H Celcon. A way of avoiding such cracking is to include calcinated magnesium oxide in the recipe. To our knowledge, Hebel is not using PFA anymore, after serious problems with a test facility in 1986.

The production of integral panels, up to say 30 m2 is possible with a one-way prestressing, in the vertical direction. Such a technology is inspired by G Dahl's development of Integral walls (Rosenborg, 1998). The BCE-system is semi-heavy building technology – characteristically, it carries a live load double its dead weight, while massive concrete carries only half.

It is believed that the BCE technology helps overcome some of the drawbacks of the traditional AAC-technology. This is rather wasteful with steel, like the HDtechnology (not to mention massive concrete on-site structures) is wasteful with concrete. This material is not to be approached as a free commodity in our modern world, due to a large embodied energy, related to cement, and severe restrictions on natural gravel. Similar restrictions will possibly be extended to crushed rock, now substituting natural gravel on Scandinavian markets. And, why destroy nature, if not absolutely necessary? In the long perspective, we feel that the prefab concrete industry will also need to approach the BCE-technology. Either way of approach, the new technology is more efficient than the origin.

Bo G. Hellers, Bo R. Schmidt, Autoclaved Aerated Concrete (AAC)-the story of a low-weight material, - Materials of 5th International Conference on Autoclaved Aerated Concrete "Securing sustainable future", Bydgoszcz, Poland, 2011, - p. 63-68.